-

ACADEMICSMET Innovation SchoolsSchool of Manufacturing Technologies School of Manufacturing Design & AI School of Robotics School of Sustainability School of Technical EducationMET Innovation CentresCentres of Excellence in Automotive Engineering Centre of Advanced Computing & AIiPMPXExecutive Programme in Smart Manufacturing

-

ADMISSIONS

- PLACEMENTS

-

CAMPUS LIFE

- PARTNERSHIP

-

ABOUT US

-

MEDIA

- CONTACT US

School of Manufacturing Technologies

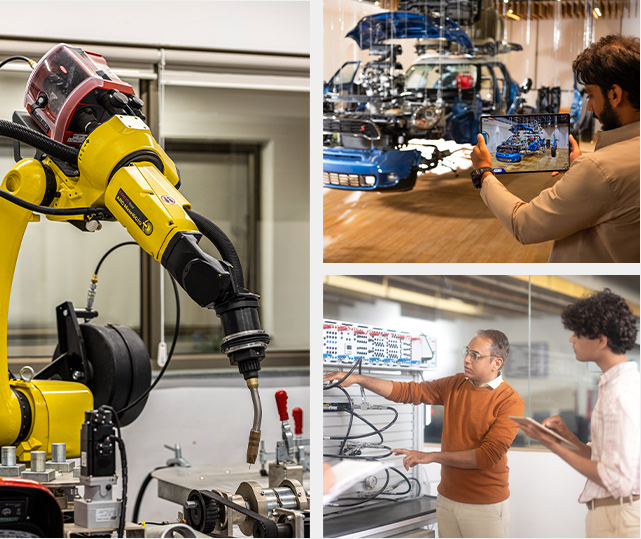

NAMTECH’s School of Manufacturing Technologies stands at the forefront of Industry 4.0, where Artificial Intelligence (AI) converges with automation, the Internet of Things (IoT) enables predictive excellence, and Digital Twins empower real-time monitoring, optimization, and continuous improvement. We integrate Augmented / Virtual Reality (AR/VR/ XR) for immersive training , and leverage Smart Supply Chain & Logistics technologies to achieve end-to-end operational intelligence, agility, and sustainability.

Our ecosystem spans the entire manufacturing lifecycle — from discrete and process automation to semiconductor and advanced materials manufacturing — seamlessly bridging Operational Technologies (OT) with Information Technologies (IT) to create a unified, data-driven, and intelligent manufacturing environment.

NAMTECH’s WorldSkills-aligned Industry 4.0 laboratories offer cutting-edge learning in Additive Manufacturing, Mechatronics, Industrial Robotics, and Smart Automation Systems, while embedding Cloud Computing, Cybersecurity, and other enabling Industry 4.0 technologies into every learning experience. These state-of-the-art facilities provide hands-on experience on globally benchmarked platforms, enabling learners to excel in national and international industrial competitions and fostering innovation, teamwork, and real-world problem-solving excellence.

The School offers a Master programme in Smart Manufacturing Technology and Management, alongside Executive and Faculty Development Programmes designed for both industry and academia. Our dedicated WorldSkills Competition Centre further reinforces our commitment to building globally competitive talent and advancing technical excellence.

At NAMTECH, we are not simply teaching manufacturing technologies — we are shaping the intelligent evolution of modern industry through innovation, integration, and insight.

Vision

NAMTECH’s School of Smart Manufacturing envisions redefining India’s industrial future by nurturing a new generation of globally competent and innovation-driven engineers. Anchored in the ethos of Make, Innovate, and Lead, the School is committed to empowering learners to become catalysts of transformation from Industry 3.0 to Industry 4.0—driving progress through automation, digitalization, and sustainable manufacturing practices.

At the heart of NAMTECH’s philosophy lies experiential, hands-on learning that bridges design, production, and emerging technologies. Through state-of-the-art Industry 4.0 micro-factories and smart labs—spanning robotics, IoT, mechatronics, cyber-physical systems, additive manufacturing, metrology, and AR/VR/XR—students acquire the skills to build intelligent, connected, and adaptive manufacturing systems. This integrated approach cultivates both technical mastery and leadership capability, preparing graduates to navigate and shape the complex digital manufacturing ecosystems of tomorrow.

The school’s mission is to create visionary engineers and industry leaders who can seamlessly merge technology with sustainability, innovation with purpose, and productivity with resilience. By equipping learners with future-ready skills and an entrepreneurial mindset, NAMTECH aspires to contribute meaningfully to India’s vision of Atmanirbhar Bharat and to the nation’s emergence as a global manufacturing powerhouse by the centenary year of independence in 2047.

Post - Graduate Engineering Programs

School of Manufacturing Technologies

School of Manufacturing Technologies

School of Manufacturing Design & AI

School of Manufacturing Design & AI

School of Sustainability

School of Sustainability

School of Robotics

School of Robotics

School of TECHNICAL EDUCATION

School of TECHNICAL EDUCATION

Dr. Vasu Velagapudi

Programme Director, School of Manufacturing Technologies

From the Programme Leader

At NAMTECH’s School of Manufacturing Technologies, we are nurturing a new generation of engineers equipped to lead India’s journey toward Atmanirbhar Bharat and global manufacturing excellence. As the nation strives to increase the manufacturing sector’s contribution from 16% to 30% of GDP by 2047, the need for industry-ready professionals with expertise in manufacturing, automation, artificial intelligence, and digital transformation has never been more critical.

The Master programme in Smart Manufacturing Technology and Management at NAMTECH offers a comprehensive, hands-on experience that blends cutting-edge Industry 4.0 technologies with strategic management practices to develop future-ready manufacturing leaders. Students gain practical exposure through WorldSkills-aligned Industry 4.0 laboratories, featuring Additive Manufacturing, Mechatronics, Industrial Robotics, Smart Automation, and Digital Twin environments. They learn to work with AI-driven control systems, IoT-enabled machinery, and AR/VR/XR simulation tools — gaining real-time experience in process monitoring, predictive analytics, and digital factory operations.

The Smart Supply Chain and Digital Manufacturing labs immerse learners in data-driven decision-making, logistics optimization, and sustainable production systems, bridging Operational Technologies (OT) with Information Technologies (IT). In addition to technical mastery, the programme integrates core management courses such as Supply Chain Management, Operational Excellence, Quality Control & Reliability Engineering, Project Management, and Product Lifecycle Management (PLM). These modules empower students to analyze, optimize, and lead complex industrial ecosystems with a focus on efficiency, quality, and sustainability.

Co-designed with world-renowned academic partners such as the Technical University of Munich (TUM) – Germany (Asia Campus) and inspired by MIT’s 2.008 Design for Manufacturing framework, the programme offers a global perspective on product design, prototyping, and scalable manufacturing.

Through immersive, application-driven learning in Industry 4.0 Mini-factories, IIoT, industrial robotics, advanced automation, and AI-enabled cyber-physical systems, students gain the ability to bridge theory with practice. They emerge as future-ready leaders capable of contributing meaningfully to the Manufacturing, Engineering, and Technology (MET) ecosystem. Our advanced laboratories in Additive Manufacturing, Precision Machine Tools, Welding 4.0, AR/VR-based Immersive Learning, and AI-powered Intelligent Manufacturing Systems further strengthen experiential learning — empowering learners to design and implement cutting-edge solutions for next-generation industries.

Through live industry projects, capstone assignments, and collaborative innovation challenges, students apply both technological and managerial principles to solve real manufacturing problems. This combination of hands-on technological training and strategic management education nurtures leaders who can envision, design, and execute intelligent manufacturing transformations — driving India’s journey toward a globally competitive, smart, and sustainable industrial future.

The School of Manufacturing Technologies stands as a hub of innovation, where technology, creativity, and purpose converge to redefine modern manufacturing. Our graduates are not only prepared to embrace change — they are equipped to lead it, building intelligent, sustainable, and connected factories that will shape the future of global industry.

Together, we are engineering the future of manufacturing.Our Future ready learning factory

Precision Engg. Lab

CAD CAM

Computer Center

Hydraulic System

Industrial automation

Precision Engg.

Life at Namtech

Infrastructure

NAMTECH offers an unparalleled campus experience with world-class infrastructure and facilities designed to inspire innovation, foster collaboration, and prepare students for the future. Our cutting-edge labs, including robotics, automation, CAD, and precision engineering facilities, provide hands-on learning opportunities using industry-grade equipment and advanced technologies like AR/VR. The campus features modern lecture halls, collaborative study spaces, and a library equipped with extensive digital resources and quiet zones for focused learning. Students benefit from comfortable l hostels with inclusive amenities, and eco-friendly green spaces that promote wellness and sustainability. At NAMTECH, every corner of the campus is designed to fuel creativity, growth, and lifelong connections—an ideal environment for shaping your future!

Sports and Recreation

We believe that a well-rounded education extends beyond the classroom, which is why we offer exceptional sports and recreation facilities designed to inspire and energize our students. For those seeking relaxation and leisure, our recreational spaces include indoor games like chess, boards, carrom and areas for yoga and meditation. With a variety of intramural sports leagues throughout the year, students have countless opportunities to stay active, develop teamwork skills, and forge lifelong friendships. At NAMTECH, your journey towards personal growth and wellness is just as important as your academic success.

College Life

College life at NAMTECH is an exhilarating journey filled with opportunities for personal growth, social engagement, and unforgettable experiences. Our vibrant campus community is a melting pot of diverse cultures, ideas, and passions, where students can forge lifelong friendships and create lasting memories. From dynamic student organizations and clubs to exciting events like cultural festivals, talent shows, and guest lectures, there’s always something happening to keep you engaged and inspired. Our dedicated student affairs team is committed to supporting your well-being and ensuring a fulfilling college experience through workshops, mentorship programs, and recreational activities. NAMTECH encourages a balanced lifestyle where academic pursuits harmonize with personal interests. Join us at NAMTECH to embark on a transformative learning experience that will shape your future and enrich your life!

Arts and Culture

At NAMTECH, arts and culture come alive through a dynamic calendar of events that promise to inspire, engage, and excite every student. From vibrant cultural festivals, craft workshops, theatre workshops to yoga, and live music performances, there’s always something happening on campus to spark creativity and foster connections. These events are more than just entertainment—they are opportunities for students to showcase their talents, explore diverse traditions, and create unforgettable memories. NAMTECH’s arts and culture scene ensures that your learning experience is as enriching as it is exhilarating.

We partner with the best

Learn from Expert Faculty with

Global Perspectives and Deep Domain Expertise

Explore Your Potential at NAMTECH

Life at NAMTECH offers a unique environment that ignites your creativity and drives innovation. You will gain hands-on experience through student-led clubs, hackathons, and cultural fests, as well as music, arts, and leadership forums.

NAMTECH’s advanced creative spaces and real-world projects with industry partners empower you to transform ideas into tangible outcomes. Our holistic approach ensures that you match your passion with purpose—whether in the lab, on stage, in sports, or leading a team.

At NAMTECH, education opens doors to personal and professional growth, shaping who you become.

Explore NAMTECH Campus

Take a Virtual Campus Tour

- Innovation Schools

- International Professional Master’s Program – Smart Manufacturing & AI

- International Professional Master’s Program – Semiconductor Manufacturing

- International Professional Master’s Program – Advanced Robotics Technology

- International Professional Master’s Program – Sustainability Engineering & Management

- International Professional Technologist Program – Automation

- International Professional Technologist Program – Industrial Robotics

- International Professional Technologist Program – Semiconductor

- International Professional Technician Certificate Program (iPTCP)

Enquire Now