The Fourth Industrial Revolution is still in its nascent state. But with the swift pace of change and disruption to business and society, the time to join in is now.

– Gary Coleman, Global Industry and Senior Client Advisor, Deloitte Consulting

Industry 4.0 exists at the point of convergence of the physical and the digital world. Smart factories operating on IoT, robotics, leverage Big Data and cloud computing for operational efficiencies. They utilise AR/VR for simulations and forecasting, which seems too far in the future to be a current reality.

However, Industry 4.0 is already here; with the digital revolution transforming the world, these new-age industries have found a solid foundation to thrive on. This is a fundamental paradigm shift in the MET sector, particularly in India, where the current government has immense emphasis on Make in India and Viksit Bharat @2047.

A successful transition to Industry 4.0 is no longer an option; it is a necessity. It is an imperative that will set India on the most efficient and quickest path to its development and growth ambitions.

Industry 4.0: The Pillars That Sustain It

Traditional manufacturing processes can no longer keep up with the demands of the nation. While they are thoroughly established and stabilised, they are not nearly efficient or scalable enough for modern requirements.

Four key technologies make the manufacturing industry smarter, more responsive, and dynamic:

Internet of Things (IoT)

IoT connects devices, machines, and systems together to collect, analyse, and log operational data in real-time. This enables the management to gather key insights for operation optimisation, automation, and enhanced decision-making. IoT also maintains machine performance and efficiency logs to prompt maintenance when it drops. This is known as “predictive maintenance” and is crucial for the optimal operation of a facility.

IoT enables remote monitoring of the entire facility for resource utilisation during periods of high or low demand, allowing adjustment of production volume with the tap of a button.

Putting this into an Indian context, the market size for IoT in manufacturing in the country is estimated to reach a value of $9.28 billion by 2027, at a CAGR of 12.87%. There is a tremendous opportunity for engineers in IoT for manufacturing, as indicated by the numbers.

Why India needs industrial IoT: This technology is crucial for establishing a stronger position for the country in the global value chain. For the Indian industries, IoT can enhance product quality and boost shop floor productivity.

AI and Machine Learning

AI and machine learning algorithms are designed to digest and analyse vast amounts of data, extracting key insights about a manufacturing facility to drive informed decisions. These technologies power predictive analytics, automated quality control and checking, intelligent robots on the floor, demand forecasting, and much more.

India’s manufacturing sector is rapidly adopting AI and ML. The industrial robotics market is estimated to reach a value of $264.10 million by 2028, whereas the industrial automation is pegged at a robust estimate of $29.43 billion (2029).

Why India needs industrial AI and machine learning: The enhanced global and domestic competition requires industries to manufacture high-quality products. AI can assist Indian industries in maintaining quality standards, detecting and reducing defects, predicting outcomes, and scaling up easily.

Robotics and Automation

Industry 4.0 takes robotics and automation one step further by introducing collaborative robots, “cobots”, on the shop floor. These robots are specifically designed to collaborate with humans side by side on the floor and are safe to work with. Where robots generally work independently based on a program, cobots interact with humans in shared work areas.

According to the International Federation of Robotics, the sales of industrial robots in India peaked at 4,945 units (installed in 2023). This represents a 45% increase in robot installations compared to 2020. The data highlights India’s first leap towards automating its industries: an opportunity ripe for the country’s budding talent.

Why India needs industrial robotics and automation: Traditional manufacturing cannot achieve high levels of efficiency, speed, consistency, and operational safety solely through manual labor. Automation can help India phase out manual labor from riskier floor tasks to achieve higher production efficiencies.

Big Data Analytics and Cloud

Smart manufacturing isn’t only about installing modernized equipment and connecting everything to a central console. Digitisation of processes entails the generation of large volumes of data, which must be managed efficiently to derive production insights.

Big Data analytics helps industries capture insights for process optimisation, waste reduction, and forecasting demands to adjust production accordingly.

Furthermore, cloud computing empowers Big Data analytics by providing a scalable and flexible digital infrastructure to house the software required for data analysis. With cloud, you gain remote access to your facility, collaboration capabilities with other professionals on the shop floor, and secure storage and handling for factory data.

Why India needs Big Data analytics and cloud: Indian industries do generate large amounts of data, but lack the technical and professional expertise to extract useful, actionable insights from it. Additionally, for many MSME industries in the country, the cost of on-premise infrastructure is steep. These factors necessitate the implementation of Big Data analytics tools and cloud computing.

Why is Industry 4.0 a Non-Negotiable for India?

India has set ambitious manufacturing goals for the future, attempting to raise the contribution of this sector from the existing 17% to 25% in the near future (IBEF). To achieve these dreams, Industry 4.0 is not merely an upgrade but a fundamental requirement for India.

Global Economic Agility

Manufacturing is a pivotal and critical activity for India to achieve economic agility and to create more jobs for the population. Industry 4.0 has the potential to enhance production efficiencies manifold.

Furthermore, there is the consideration of global competitiveness, an aspect that India has included in its Viksit Bharat @2047 ambitions. To move up in global value chains, India must drastically reimagine its manufacturing, engineering, and technology approaches and modernize them.

Where India’s services exports increased nearly twofold between 2014 and 2024, the manufacturing exports have remained modest at 1.8%. Industry 4.0 is critical to enhancing India’s manufacturing capacity and efficiency.

With automation, critical production insights, remote access, and robotic assistance, India’s manufacturing sector can be overhauled to produce high-quality output with consistency and on demand. This is sure to give the nation a compelling position in the global markets for manufacturing exports.

Addressing Productivity Gaps

Traditional manufacturing practices that still exist in India are fraught with inefficiencies, dependency on the availability of manual labor, inconsistencies in quality, downtime, and other issues. With the introduction of Industry 4.0, it is possible to overcome these challenges and establish a more stable manufacturing ecosystem with fewer external dependencies.

India should explore a hybrid system where AI and automation kick in when there is a labor shortage or skill gap to ease into Industry 4.0 slowly. Technologies like AI and IoT have tremendous potential to enable faster production cycles, reduce errors, and ensure continuous run times, allowing for round-the-clock production wherever possible.

Innovation and Resilience

As a developing nation, India needs to foster indigenous innovation and resilience in response to socioeconomic and geopolitical events. This ensures production preparedness even in adverse situations.

Innovation needs to be at the heart of the manufacturing industry, moving beyond labor-intensive roles and employing skilled, digital-native talent to drive production and design. Even in the face of global disruptions, Industry 4.0 can help India establish an agile supply chain that plugs the gaps in times of need.

For example, AI and IoT modules can forecast upcoming supply chain disturbances due to geopolitical factors, automatically triggering an adjustment to the output while initiating the prior storage of raw materials.

As is evident, Industry 4.0 uses a multifaceted approach towards production, ensuring that it covers all bases for the uninterrupted continuation of production. In this regard, India can benefit significantly from Industry 4.0.

Seize The Future of MET with NAMTECH

Turning India into a globally competitive manufacturing hub is the country’s greatest and yet untapped potential to steer job creation. Industry 4.0 introduces a multitude of new roles that require specialized skills in areas such as data analytics, AI/ML engineering, robotics and programming, cybersecurity, Digital Twin creation, additive manufacturing, and more.

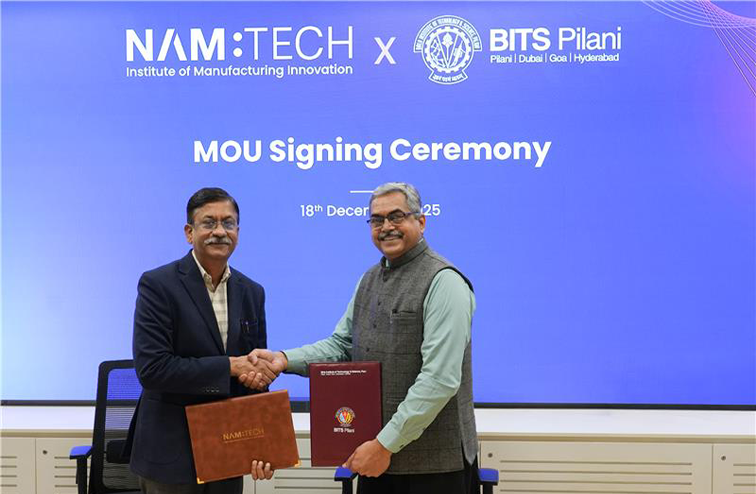

To ensure that the Indian workforce is ready for this new leap into manufacturing, there needs to be an overhaul in the education sector as well. NAMTECH envisions a curriculum that emphasizes experiential, hands-on learning, focusing on project-based, practical tasks. The institute’s programs emphasise learning from real-world case studies with industry specialists to gain shop-floor understanding of how the industry functions.

NAMTECH is dedicated to helping India develop 21st-century skills through industry-academia collaborations at a global level. This highly specialised approach is ideal for helping create a future-ready workforce for India that is ready to take on the challenges of Industry 4.0 and adapt to suit India’s ambitions of a Viksit Bharat @2047.

Become a part of the NAMTECH revolution for making India a manufacturing hub through facilitating a modernised workforce. Browse our programs now.

12 June, 2025