Introduction

In today’s manufacturing landscape, technological change is outpacing the ability of many institutions and workforces to keep up. Factories are evolving into adaptive, digitally connected environments where industrial AI, robotics, and software-defined automation enable machines and people to collaborate seamlessly.

Data flows continuously across systems, powering real-time decision-making and agility across the value chain. Yet the next generation of talent often finds it challenging to match the demands of this new era—where resilience, flexibility, and the ability to harness advanced technology are essential to thrive.

This is the gap that New Age Makers’ Institute of Technology (NAMTECH) was founded to bridge.

NAMTECH is grounded in the belief that students thrive when education mirrors real-world manufacturing environments shaped by industry needs, not solely textbook theory.

Rather than preparing learners for the future in abstraction, the institute brings industry to the classroom through deeply integrated partnerships, practical labs, and curricula designed with direct input from manufacturing leaders. In doing so, NAMTECH builds the skills, experience, and technology fluency that modern industry demands — mirroring how leading initiatives worldwide are redefining workforce preparation through hands-on training, industry collaboration, and future-focused education.

The Challenge

While manufacturing technologies have advanced significantly, traditional technical education has struggled to keep pace, leaving many graduates strong in theory but with limited exposure to real industrial environments, and requiring substantial onboarding before they can contribute meaningfully on the shop floor. At NAMTECH, we recognised this challenge early and designed a model that ensures students are not only job-ready but innovation-ready.

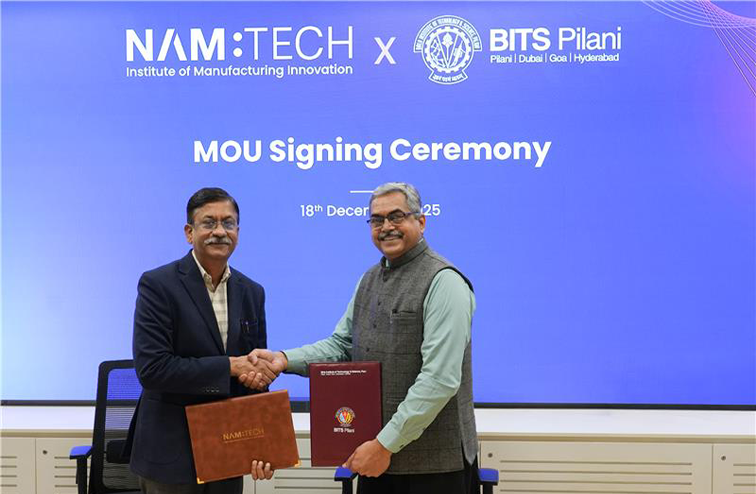

Inspired by approaches like those in MIT’s Initiative for New Manufacturing, which blends practical education with industry collaboration to prepare talent for the evolving industrial landscape, NAMTECH’s techno-managerial master programmes for high-growth sectors such as smart manufacturing, robotics, semiconductors, sustainability, automotive engineering, and data analytics & AI are structured to be nearly 70% practical and built on an industry-academic pedagogy.

This immersive design enables students to solve real-world problems and equips them to be job-ready from day one — mirroring global efforts to expand talent pipelines, integrate advanced technologies, and align education with industry needs.

NAMTECH’s Approach: Learning That Replicates the Real World

- An Industry-Shaped Curriculum

While manufacturing technologies have advanced significantly, traditional technical education has struggled to keep pace, leaving many graduates strong in theory but with limited exposure to real industrial environments, and requiring substantial onboarding before they can contribute meaningfully on the shop floor. At NAMTECH, we recognised this challenge early and designed a model that ensures students are not only job-ready but innovation-ready.

Inspired by approaches like those in MIT’s Initiative for New Manufacturing, which blends practical education with industry collaboration to prepare talent for the evolving industrial landscape, NAMTECH’s techno-managerial master programmes for high-growth sectors such as smart manufacturing, robotics, semiconductors, sustainability, automotive engineering, and data analytics & AI are structured to be nearly 70% practical and built on an industry-academic pedagogy. This immersive design enables students to solve real-world problems and equips them to be job-ready from day one — mirroring global efforts to expand talent pipelines, integrate advanced technologies, and align education with industry needs.

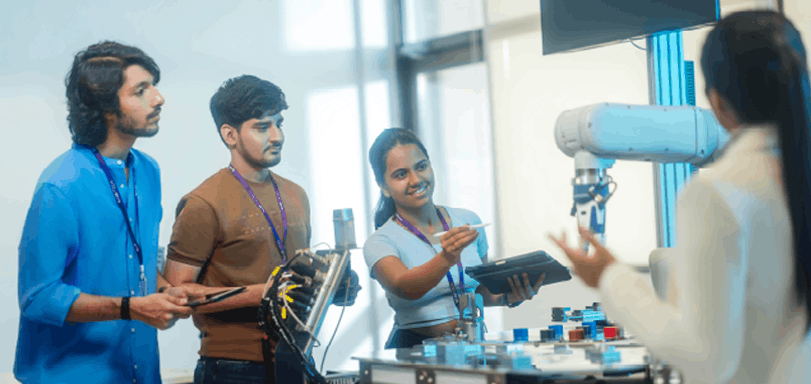

- Labs That Function Like Real Production Floors

Echoing ArcelorMittal Nippon Steel (AMNS), our founding partner’s emphasis on learning through real-world manufacturing environments, NAMTECH’s Smart Manufacturing labs are designed to function like live production floors rather than academic classrooms. Equipped with advanced industrial machinery, automation systems, IIoT networks, digital twins, and integrated platforms, these labs replicate actual factory ecosystems. Students learn by doing: configuring systems, diagnosing failures, and optimizing workflows, gaining a practical understanding of how complex industrial operations function at scale.

- Problem-Solving as a Core Learning Habit

Echoing ArcelorMittal Nippon Steel (AMNS), our founding partner’s emphasis on learning through real-world manufacturing environments, NAMTECH’s Smart Manufacturing labs are designed to function like live production floors rather than academic classrooms. Equipped with advanced industrial machinery, automation systems, IIoT networks, digital twins, and integrated platforms, these labs replicate actual factory ecosystems. Students learn by doing: configuring systems, diagnosing failures, and optimizing workflows, gaining a practical understanding of how complex industrial operations function at scale.

For instance, in the Master in Smart Manufacturing Technology and Management programme, the Yo-Yo project is designed to take students through the entire journey of product development, starting with conceptual design and material selection, and moving through machining, production processes, quality control, financial management and final assembly. The project mirrors real-life

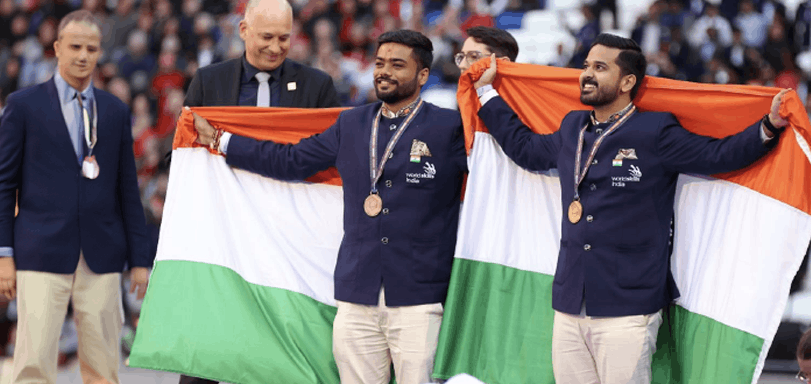

Real-World Validation: Success at the WorldSkills 2024 Competition

The effectiveness of this learning model came to light at the WorldSkills Competition 2024 in Lyon, France, where NAMTECH’s learners represented India in the Industry 4.0 category. This category is considered one of the most challenging because it demands a combination of engineering, programming, analytics, and real-time decision-making.

Over five intensely demanding days, participants worked as Digital Production Systems Technicians, dealing with tasks that mirrored actual factory operations.

They were tested across:

- Automation using digital twins and simulations

- Connectivity and IIoT for cloud-based monitoring and secure data flow

- Data Analytics and AI to optimise processes through real-time insights

- System Integration involving PLCs, HMIs, SCADA and MES systems

- Real-Time Problem-Solving, where every mistake had visible consequences

“The gold medal at India Skills 2024 and the bronze Medal at World Skill 2024 in the industry 4.0 skill trade testify to the exceptional foundation I built at NAMTECH with the help of dedicated faculty, state-of-the-art facilities and exceptional mentorship.”

– DhrumilkumarGandhi

Batch of 2023-2024

The Larger Impact: Beyond Skills, Building Mindsets

Students who go through NAMTECH’s programmes do not just walk away with technical knowledge. They develop a mindset that today’s industry deeply values.

They learn how to:

- Operate confidently within complex, digitally enabled industrial systems

- Diagnose and analyse challenges independently, rather than relying on step-by-step instructions

- Integrate and orchestrate multiple technologies and platforms as interconnected systems

- Innovate and improve processes, instead of merely following established procedures

- Translate learning into real-world impact: as entrepreneurs, problem solvers, and creators of next-generation solutions

This is the real value of NAMTECH’s campus–industry collaboration model. It transforms students into professionals who can contribute immediately and grow quickly because they understand how real factories think and function.

“We have been hiring students from NAMTECH for the past two years, and our experience has been very positive. The students bring strong skill levels, are resourceful, and add value to the organization.”

– Electrotherm

Conclusion

NAMTECH’s approach underscores that meaningful industry collaboration is not a peripheral enhancement but the very foundation of effective technical education. By rethinking how students learn, providing access to world-class, application-driven labs, and embedding real industry expectations directly into the curriculum, the institute is developing talent aligned with the evolving needs of advanced manufacturing.

The bronze medal at WorldSkills 2024 is more than an accolade, it is tangible evidence that education rooted in real-world problem solving delivers globally competitive outcomes. More importantly, it demonstrates the power of an ecosystem that challenges students not merely to absorb knowledge, but to think critically, create boldly, and innovate with purpose.

Through this model, NAMTECH is cultivating future-ready professionals who will help shape the next era of manufacturing, not just participate in it.

Designation : Director - Corporate Partnerships & Placements

19 January, 2026