Manufacturing worldwide is moving from Industry 4.0 to Industry 5.0, where the focus is not only on automation but on collaboration between humans and intelligent systems. For India’s technical education system, especially ITIs and polytechnics, this shift is a wake-up call. Training can no longer stop at basic workshop practices; it must reflect how real factories operate today and how they will run tomorrow.

Bridging the Skills Gap

Traditional mechanical skills are still important, but they are no longer enough. Modern shop floors run on automation, IoT-enabled machines, CNC systems, robotics, and digital manufacturing tools. If students are trained only on conventional lathes and basic wiring, they will struggle the moment they enter an Industry 4.0 or 5.0 workplace.

Today’s technicians need to understand how machines communicate with each other, how data from sensors is collected and interpreted, and how systems such as PLCs and SCADA are programmed and monitored. In other words, they must be comfortable with cyber-physical systems, not just physical tools.

Institutes like NAMTECH are addressing this gap by training 1,800+ ITI students by setting up 5 physical component labs across 5 different ITI centres in Gujarat — Precision Engineering, Advanced Welding, Electrical Automation, Industrial Automation, and Advanced Automotive in the state of Gujarat. This is further supported by labs-on-wheels, online learning modules, and AR/VR based training, reaching an additional 10 ITIs for wider impact.

Why Interdisciplinary Learning Matters

Manufacturing today sits at the intersection of mechanical, electrical, and computer engineering. A siloed approach, where each discipline is taught separately with minimal integration, no longer serves students well.

Technical institutes need to provide students with hands-on exposure to modern equipment, simulation software, and smart factory practices. When students learn to diagnose and solve problems in integrated, real-world environments, they are better prepared for the complexity of actual industrial operations.

Students in the NAMTECH iPTP programme are taught by industry experts on the actual machinery used in factories, ensuring there is no gap between what is taught and what is needed. Students are trained not only to run a machine, but to manage an entire shop floor. This approach enables both upskilling and cross-skilling at the same time.

Building an Ecosystem: Academia and Industry Together

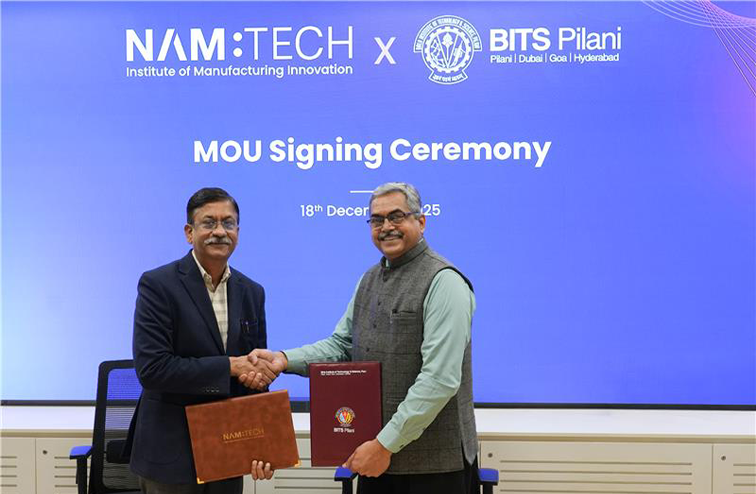

No single institute can do this alone. The most effective models are ecosystem-driven, where academia, industry, and government work together. Institutions like NAMTECH are building this kind of ecosystem by connecting students with industry partners, government initiatives, and international academic expertise, by providing 6 months of industry immersions.

Instead of learning only from textbooks, students deal with real factory problems, participate in experiential learning modules, and receive training on updated equipment and processes that reflect current industry standards.

Policy Support and the Road Ahead

This shift is not happening in isolation. National programmes such as Skill India, Pradhan Mantri Kaushal Vikas Yojana (PMKVY), and the National Education Policy (NEP) actively encourage the adoption of Industry 4.0 technologies in training. There is a clear push to modernise ITI’s labs, upgrade facilities, and benchmark against global manufacturing standards.

As more factories adopt IoT-enabled machinery, automated material handling, advanced CNC technologies, digital quality systems, and ERP-integrated shop floors, these skills are becoming baseline expectations, even for entry-level roles.

With entry-level skill requirements rising, the country needs more skill development institutes that can produce industry-ready professionals from day one. In line with this, NAMTECH is partnering with state governments to upgrade ITI centres with the support of industry partners, ensuring better education and employability-focused skill development for students. The goal is to reach three million students by 2035.

To truly prepare the next generation of technicians, technical institutions must prioritise advanced training and digital competence. When students are exposed to smart manufacturing technologies and learn in environments aligned with real industry practice, they graduate not just as machine operators, but as confident, capable contributors to the future of manufacturing.

When education gives both knowledge and capability, students do not just get jobs.

They create opportunities. Let us build that future.

16 January, 2026