NAMTECH is on a mission to continuously overhaul the standard of manufacturing education through the creation of a unique, first-of-its-kind experiential learning module in India. The “Yo-Yo programme”, which is inspired by the globally recognized hands-on course (2.008 Design and Manufacturing II), taught in the Department of Mechanical Engineering (MechE) at the Massachusetts Institute of Technology (MIT). The module – 2.008N has been specially created for NAMTECH and subsequently merged with the Master in Smart Manufacturing Technology and Management programme

This stems from a collaboration between NAMTECH and MIT MechE through a signed Memorandum of Understanding (MoU). The aim is to blend the experientiality and hands-on component of MIT MechE’s renowned Mechanical Engineering course in manufacturing processes (2.008) with NAMTECH’s Industry 4.0 and smart manufacturing focus through integration of AR/VR content and phygital labs.

The Yo-Yo programme creatively and technically uses the making of a yo-yo as a full learning model. Through this project, students are taken through the entire journey of product development, starting with the conceptual design and material selection, and further passing through machining, production processes, quality control, and final assembly.

The Programme Helps students in Multiple Ways

The Yo-Yo programme enables students to experience a fully experiential learning model to:

1. Drive practical, end-to-end learning

Students are not only taught manufacturing principles, but they are obliged to invent a working product from the very beginning. This changes the learning held in a classroom into practical skills.

2. Understand Design-For-Manufacturing (DFM)

By taking real design and production decisions, students learn how the use of different materials, tolerances, and processes affect performance, cost, efficiency, and scalability.

3. Build precision and quality awareness

While building a truly functional yo-yo, students learn to bring quality control in balance, bearings, surface finish, and accuracy in assembly. These factors introduce students to the issues of precision in manufacturing.

4. Expose to industry 4.0 technologies

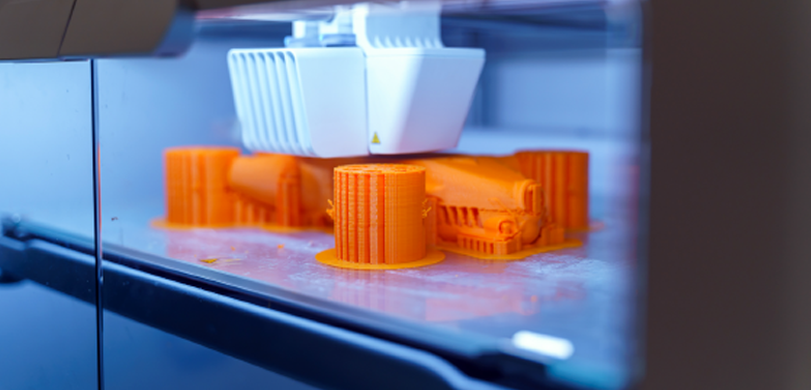

The yo-yo project exposes students to multiple Industry 4.0 technologies such as automation systems, 3D printing, injection moulding, and industrial IoT among others. By making the whole process a technological marvel, students see how a traditional manufacturing process can turn into a high-tech one.

5. Enable innovation & skill development

The programme takes iterative thinking, problem-solving, optimisation, and continuous improvement using cost and quality, system and supply chain, sustainability as its main points — these will enhance their leadership skills in manufacturing.

6. Improve industry readiness

Engineering graduates, often fall short of direct product-building experience in automotive, toy & plastic component making sectors. This programme closes that loophole and makes them job-ready with the skills that are in demand by global manufacturing giants.

7. Bring parity between engineers from core & non-core backgrounds

This programme is a common platform for students working in both core and non-core engineering fields. It helps students learn how to carry out 5-S principles, Just in Time (JIT) and implement sustainable manufacturing practices at scale. It is ideal for anyone who wants to work in the field of manufacturing, be it in automotive, aero-space, semiconductors, or other related areas.

“The YO-YO programme has emerged as a remarkably effective pedagogical tool, enabling students to engage with engineering in its most authentic form. By conceiving, designing, machining, and validating a fully functional yo-yo, students translate theoretical principles into tangible mastery. Throughout this process, we observe substantial growth in their technical judgment, CAD/CAM proficiency, manufacturing literacy, and iterative problem-solving. What appears to be a simple object becomes an elegant vehicle for cultivating professional engineering mindset, design rigor, and an appreciation for the complete product-realization cycle.”

– Ujjaval Modi, Senior Lecturer at NAMTECH

NAMTECH’s Distinctive USP

This Yo-Yo programme is a significant factor that distinguishes NAMTECH from the others:

- It is the first time any Indian institute is offering an experiential Yo-Yo project as part of a formal curriculum across all programmes.

- From material selection to product realisation and understanding the scalability of manufacturing, the programme makes students industry-ready from day one as it offers a balanced mix of technical and managerial learning.

- Along with the programme, NAMTECH offers six months to one year of industry immersion where students engage with real-world challenges and apply the learning they have gained at NAMTECH.

- The academic and industry pedagogy supports placement in high-growth sectors such as automotive, smart manufacturing, and semiconductors with leading companies in these domains.

Your Path to Advanced Manufacturing Starts Here

The Yo-Yo programme is integral to the curriculum of Master in Smart Manufacturing Technology and Management at NAMTECH which equips the graduates with the necessary skill to grab the opportunities that come with the concurrence of manufacturing, automation, and digital transformation.

The programme is designed for future-ready techno-managers.

The question is, are you one of them?

Designation : Assistant Professor

19 December, 2025