“We cannot wait until there are massive dislocations in our society to prepare for the Fourth Industrial Revolution.”

– Robert J. Shiller, Yale University.

Industry 4.0 holds a transformative power that can change the way economies grow, including India. AI, IoT, robotics and automation, Big Data, cloud computing, and other technologies contribute to creating smart and autonomous factories that operate with high system efficiency.

With such advancements in India’s industrial environment, the workforce must also re imagine itself and, move beyond traditional roles and adopt new-age learning and training.

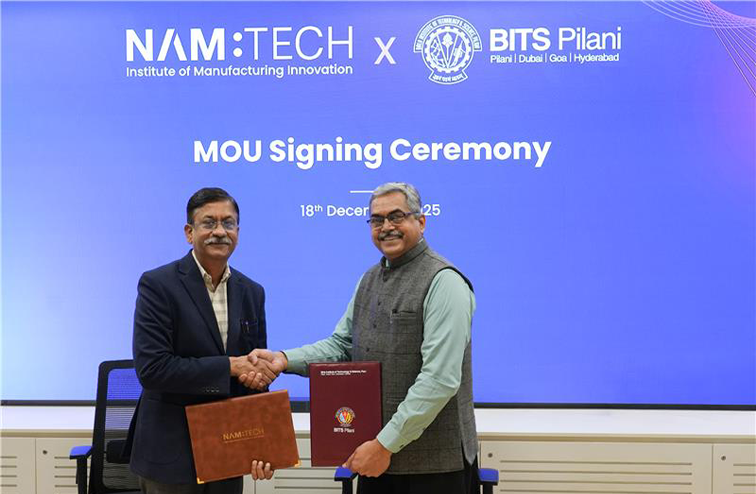

NAMTECH (New Age Makers Institute of Technology) equips engineering graduates with practical, interdisciplinary skills for Industry 4.0. Through real-world learning, smart factory simulations, and expert mentorship, it bridges the gap between theory and industry, preparing students to lead the future of Indian manufacturing.

It’s time to explore how continuous, Industry 4.0-aligned education beyond a traditional B.E./B. Tech can explore better opportunities—and how NAMTECH is at the forefront of that transformation.

The Reality of Educational Traditions

Theoretical grounding is a crucial aspect of learning, but it isn’t enough by itself. Professionals must also understand how to apply their learning to the real world in order to innovate and design efficient solutions.

The same concept applies to professionals in engineering and technology. With Industry 4.0 rapidly setting in and laying the foundations of the country, the professionals must step up to the challenge and reskill.

Employability

The skill of the workforce severely impacts employability as India embraces the Fourth Industrial Revolution.

According to AICTE, out of the 6.01 million students enrolled across undergraduate, postgraduate, and diploma programs in engineering between 2019 and 2023, about 43% were successfully placed in jobs.

This data highlights that there is a significant gap between workforce availability and employability.

What the MET graduates of India require is a strategic relearning of the concepts that make their knowledge actionable and relevant to Industry 4.0.

Courses oriented specifically for the new-age industries make it possible for these graduates to contribute their talents to the nation’s development.

Curriculum lag

Traditional learning often relies on scientific knowledge passed down over the ages, with little to no focus on emerging technologies. This makes technologies like AI and IoT seem fairly alien to graduates who aren’t already familiar with their applications.

Universities need to frequently update their curricula to accommodate emerging technologies, enabling students to remain relevant in the market.

Limited practical exposure

The current curriculum focuses on theoretical lab exercises rather than practical application. While students are familiar with industrial machinery and its purpose, they often lack sufficient preparation to innovate due to knowledge gaps.

Furthermore, India needs more internships and projects under the direct supervision of niche experts to help transform the skill development process.

Industry frustration

According to CII data, the digital maturity across manufacturers in India is non-uniform. On a scale of 5 (with 5 being the highest digital maturity), large enterprises score 3.4, medium-sized companies score 2.9, and micro, small, and medium-sized enterprises (MSMEs) lag with a score of 2.4.

Additionally, the top 25% of manufacturers have already reached a score of 4.3, whereas the bottom 25% have a score of 1.9 at their highest.

This disparity in adopting Industry 4.0 solutions reflects the urgent need for digital literacy and the necessity for a more up-to-date, relevant workforce—especially in high-precision sectors like semiconductor manufacturing, where digital excellence and skilled talent are critical to success.

Where 85% of business leaders prioritize digital adoption, only 30% have been able to scale their initiatives.

This calls for a second look at the way India prepares its MET professionals— a large-scale overhaul is needed to plug the gaps between skill and industrial requirements.

NAMTECH: Filling in The Blanks with Modernised Learning

As established, there is a significant gap between the existing MET professionals in our country and the required skills to successfully implement Industry 4.0 in India.

NAMTECH, an Industry 4.0-focused reskilling institute, recognizes the importance of relevant, practical learning and closes the gap with expertly designed Industry 4.0 courses:

| Aspects | Traditional graduate program | NAMTECH Industry 4.0 program |

| Core technical knowledge | Sound theoretical foundation | Applied knowledge of Industry 4.0 technologies |

| Practical exposure | Generalised lab work, theoretical projects, and equipment that is not regularly updated | Smart factory simulations, real-time data analytics, industrial projects using robots and advanced machinery, etc. |

| Interdisciplinary skills | Isolated learning focusing on the engineering niche of choice | Learning in mechatronics, data science (manufacturing & AI manufacturing), IT-OT convergence, and cross-functional team collaboration |

| Problem-solving | Emphasis on solving textbook problems using established principles | Analysing complex issues related to system failures, system optimisation, predictive maintenance, and more |

| Tools and tech | Standard software that is rarely updated (like CAD, STAAD, etc.) | Industry 4.0-relevant software like SCADA, MES, PLCs, IIoT platforms, AI/ML frameworks, and more |

| Soft skills | Occasional extracurricular programs to impart soft skills | Emphasis on critical thinking, adaptability, collaboration, and continuous learning aptitude across all stages of learning |

| Relevance to Industry 4.0 | Limited input from niche professionals | Curriculum co-created with industry professionals with real-time projects, direct mentorship and exposure to best practices around the globe |

The NAMTECH Differentiator for B.E./B.Tech Students

India’s ambitious leap towards adopting Industry 4.0 practices has put institutions focused on new-age manufacturing in a crucial spot.

NAMTECH stands out with its Industry 4.0 training and courses co-created with niche professionals who have worked and gained experience in smart manufacturing.

NAMTECH’s curricula directly address India’s pressing need for digitally comfortable talent, with an ambitious mission of training 3 million candidates in MET by the end of 2025.

Relevant learning

NAMTECH’s Industry 4.0 programs are co-created by industry professionals and regularly updated in collaboration with leading industry partners. The institute has solid alliances with prominent companies such as ABB, Festo, Schneider, Cisco, and ASDC, providing students with access to modern technologies and real-world industrial experience.

Conscious Technologists

Industry 4.0 isn’t merely about re imagining manufacturing but also about consideration for the ethical implications of modern technologies. NAMTECH incorporates sustainability, well-being, global industrial dynamics, and economics into the learning fabric to give it the perspective of reality.

“Innovation Schools” model

Breaking the barriers of siloed learning that focuses on a single speciality, NAMTECH approaches training with an interdisciplinary view.

The training combines multiple pathways covering several niches and their interplay to introduce complexity and depth to the curriculum. It enhances students’ understanding of a problem and polishes their approach towards solutions.

Global collaboration

NAMTECH fosters educational partnerships with reputable schools of innovation and technology worldwide, including the Technical University of Munich, Asia, Purdue University Northwest in the USA, and many more. These collaborations enable NAMTECH to deliver expertly designed courses, experiential learning, and core knowledge of Industry 4.0 to students.

What Are The Benefits?

The benefits of enrolling in the NAMTECH Industry 4.0 program are tangible for B.E./B.Tech students:

Improved employability

Large enterprises with high digital maturity actively seek out professionals trained in Industry 4.0 practices. This enhances the employability of the B.E./B. Tech graduates who are seeking to make contributions to India’s growth by way of talent and skill.

Higher earning potential

Gaining specialised, practical skills in modern technologies such as IoT and AI commands a premium package compared to candidates with traditional degrees. Industry 4.0 has compelled employers to seek out individuals who possess the knowledge to apply it rather than hiring individuals who merely possess knowledge.

Immediate contribution to the industry

NAMTECH integrates hands-on experience into its curriculum, exposing the candidates to an industrial environment and work patterns during training. This way, candidates can join a facility and start contributing to production from day one, leading to enhanced job satisfaction levels.

Accelerated rise in career

Early exposure to Industry 4.0 environment and practices provides candidates with the opportunity to secure seniority in the niche. It enhances their chances of rapid career advancement, aiming for leadership roles and acquiring skills for adapting to technological shifts along the way.

A Blueprint for The Future: Practical, Applicable Skills with NAMTECH

Change is the only constant. This is especially true in the context of technology; with each new innovation, a novel concept is created, which impacts everything else around it. Global industries must adapt their workflows and processes to adopt more efficient solutions for enhanced outputs and quality.

To realize its dreams of SAMARTH Udyog and Viksit Bharat @2047, it is crucial for India to embrace Industry 4.0 with full preparedness. Including infrastructure and digital awareness, India needs to invest in updating its talent pool as well, and this is the mission that NAMTECH has undertaken to achieve.

Through its Industry 4.0 program, NAMTECH aims to connect India’s talent force with the country’s Industry 4.0 landscape through reskilling and upskilling.

Visit the website to know how!

17 June, 2025