If you’re stuck choosing between a masters in smart manufacturing and a masters in manufacturing engineering, you’re not being “confused”—the names are genuinely similar, but the careers they shape can feel very different.

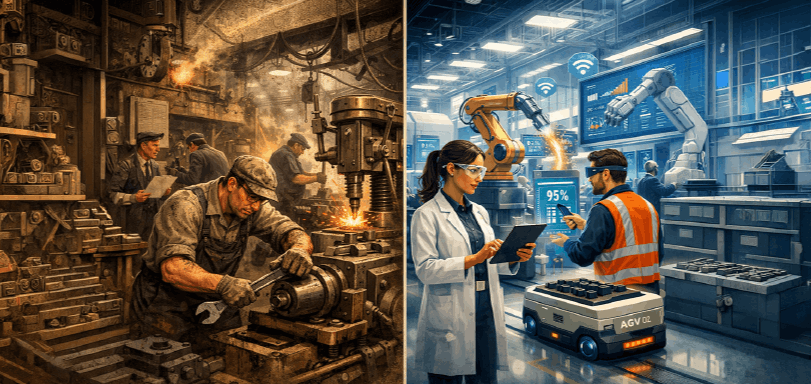

The simplest way to think about it is this: traditional manufacturing degrees train you to run and improve factories as they’ve historically operated, while smart manufacturing degrees train you to run and upgrade factories as they’re becoming—connected, automated, and heavily data-driven.

What is a traditional manufacturing degree?

A masters in manufacturing engineering is built around the fundamentals of how products are made at scale. You learn how to make production reliable, efficient, and repeatable. The focus is usually on process improvement, quality management, materials and methods, and operations planning. If you imagine a factory as a well-run system of machines, people, and schedules, this degree teaches you how to keep that system stable and constantly improve it without breaking what already works.

This is a strong fit if you see yourself in plant operations, production leadership, industrial engineering roles, or quality and continuous improvement teams—especially in environments where safety, consistency, and cost control are the main game.

What is masters in smart manufacturing?

A masters in smart manufacturing shifts the spotlight to what’s changing manufacturing right now: sensors, automation, robotics, software, and data. The factory isn’t just a physical space anymore—it’s also a digital system that produces information all day, and the best factories use that information to make better decisions faster.

This is where ideas like Industry 4.0 come in, along with digital twins, predictive maintenance, connected machines, and analytics-led performance improvement.

How are these degrees different in real-world skills?

Here’s the real difference that shows up on the job. Traditional manufacturing training makes you great at diagnosing process issues through engineering thinking and structured improvement methods.

Smart manufacturing training makes you great at diagnosing issues through data, automation, and system visibility. Instead of asking only, “What’s happening on the line?” you also ask, “What does the data say is about to happen, and how do we prevent it?”

In practice, traditional degrees make you stronger at shop-floor fundamentals and operational control whereas smart manufacturing makes you stronger at connecting manufacturing with technology—so you can build systems that predict downtime, track defects earlier, and optimise performance across the whole operation.

Which degree has better career opportunities?

Both can lead to excellent careers, but they typically point to different paths. A masters in manufacturing engineering aligns well with roles like production engineer, operations manager, quality leader, and plant management. A masters in smart manufacturing is more likely to put you in automation, digital transformation, smart factory engineering, manufacturing systems, or analytics-heavy roles where the expectation is that you can work comfortably with both engineers and tech teams.

The reason smart manufacturing roles are growing fast is simple: factories are investing heavily in automation and visibility because it reduces cost, improves output, and improves quality. Companies want people who can translate that investment into real performance gains.

Which one should you choose?

If you like hands-on manufacturing, stable systems, and want to lead production operations, a masters in manufacturing engineering is a solid, respected option. If you’re excited by robotics, data, automation, and the idea of building factories that “think” and respond in real time, a masters in smart manufacturing route will likely feel more future-proof. And if what you want is a degree that balances engineering depth with management fundamentals—then NAMTECH’s master in smart manufacturing Technology & management can be a strong bridge between the two.

Bottom line: manufacturing is becoming a tech industry whether people admit it or not. Pick the degree that matches the kind of problems you want to solve—process problems, or process + technology problems. Either way, you’re not behind. You’re literally doing the smart thing by thinking this through before you commit.

17 February, 2026