India has the largest youth population in the world, with 65% of the population under the age of 35. This has given the country the necessary propulsion for economic growth and talent cultivation.

Where India used to be a largely agrarian economy, its focus has since shifted to becoming self-reliant through empowering its MET sector (Manufacturing, Engineering, and Technology). In the global economic landscape, this move aims to put India on the map for FDIs and other growth-boosting initiatives.

The growth of manufacturing is closely interlinked with India’s GDP, and it depends on sustainable and inclusive development with the help of homegrown talent. Let’s explore how talent, manufacturing, and GDP play their roles in India’s growth.

Contribution of the Macroeconomic Trends to India’s Growth

The macroeconomic lens of India consists of three pillars that steer its growth trajectory:

- GDP

- Revival of Manufacturing

- Role of Modern Technologies

Let’s break it down further.

GDP

According to the IMF, India has marked consistent growth that surpasses the global averages in the past decade. In 2022/23, the country clocked a GDP total of $3.7 trillion, with a per-capita income of $2,612, which was 11.64% higher than the previous year.

These numbers show that India is already on its way towards its goal of becoming a developed nation by 2075, propelled by its vast youth population and skilled talent.

Revival of Manufacturing

India’s manufacturing sector currently accounts for 17% of the total GDP. With the “Make in India” initiative, the foundation was already set for India to become self-reliant in areas such as technology and consumer goods.

Additionally, the government has extended support for this movement through Production Linked Incentives (PLI schemes). It aims to boost domestic manufacturing in key sectors like electronics, automotive, and pharmaceuticals. This will open up numerous opportunities for young people to contribute their talents to the MET sector.

The manufacturing sector in the country is experiencing a steady boost with FDIs amounting to $165.1 billion – a 69% increase – over the past decade, also driven by PLIs. In fact, the industry is estimated to reach $1 trillion by 2026 in India, laying a robust foundation for aspirants to participate in the sector and bring innovation to the growth equation.

Role of Modern Technologies

Reports say that the Government of India (GoI) has plans to make technology a 25% contributor to the nation’s GDP by 2026.

According to reports by Invest India, the country’s industrial automation market is estimated to reach $29.43 billion by 2029. The GoI has announced SAMARTH Udyog Bharat 4.0, India’s own Industry 4.0 initiative through the Ministry of Heavy Industry and Public Enterprises, to enhance the competitiveness of the Indian Capital Goods sector.

These numbers promise numerous opportunities for job seekers in the country’s digital and technology sector.

Challenges: 3 Key Hurdles India Must Navigate

India’s ambitious development goals are practically achievable with exhaustive planning from the get-go. The development plans, however, must include solutions for the following three key challenges:

1. Socioeconomic Disparities

As a developing nation, India experiences spontaneous and unplanned bursts of development, which are not evenly spread across the urban-rural landscape. Furthermore, India’s education system focuses on imparting conceptual rather than practical knowledge.

More social disparities appear in the job profiles to which the Indian population has access. The informal economy commands 80% of jobs, whereas the formal economy only 20%.

There is a need for reform in the country’s social fabric in the way it approaches employment and innovation.

2. Skill Gaps

According to the Future of Jobs report by the World Economic Forum, 38% of Indian workers’ core skills are expected to be disrupted by AI. There is a need for systematic reskilling and upskilling of the youth workforce to align with the needs of Industry 4.0.

It is imperative that the reskilling focus more on digital familiarity and nativeness, the use and application of AI, and data engineering and security roles.

3. Infrastructure and Logistics

Reports highlight that 40% of the Indian population will be urban residents by 2030. There will also be developed or developing urban towns with similar income profiles in the country.

The challenge would be to provide and maintain infrastructure and logistics in these booming areas, which could significantly impact the quality of life for India’s talented population.

Quality of life directly impacts work productivity and attendance. It highlights the need for reform in physical connectivity (roads and public transport), the provision of basic utility services (electricity), and financial inclusion of the population.

These challenges are simple to solve if integrated into India’s development plans.

Opportunities: The Manufacturing Path for India

With the introduction of AI and other modern technologies, the landscape of India’s manufacturing sector is rapidly evolving. This presents a tremendous opportunity for job creation in newer roles, and a boost in demand for manufacturing skills:

New-Age Manufacturing

Traditional manufacturing methodologies are giving way to smart manufacturing, which makes use of the Internet of Things and connected devices for higher efficiencies. The integration of artificial intelligence, machine learning, robotics, and automation is rapidly transforming the way factories and manufacturing facilities operate.

India puts heavy focus on the manufacturing of semiconductors, electric valves, and clean energy in its new development plan. 35% of manufacturing companies in India wish to focus on semiconductors and computing technologies going forward, according to WEF reports.

To fuel this ambition, India now requires a full-fledged force of engineers in manufacturing for its 4.0 industries.

In-Demand Engineering Roles

The rise of Industry 4.0 and new age manufacturing creates countless new roles for engineers in the niche:

- Automation engineers: Design and implement intelligent and automated production lines

- IoT systems engineers: Monitor manufacturing facilities over connected technologies

- AI and ML specialists: Handle manufacturing data and develop predictive maintenance tools

- Robotics engineers: Design, run, and integrate robotic-assisted tools in manufacturing

- Materials engineers: Innovate advanced materials for new-age manufacturing

- ESG specialists: Focus on the impact of manufacturing on the world

- Semiconductor process engineers: Contribute to India’s semiconductor-specific ambitions

Skill Development Pathways

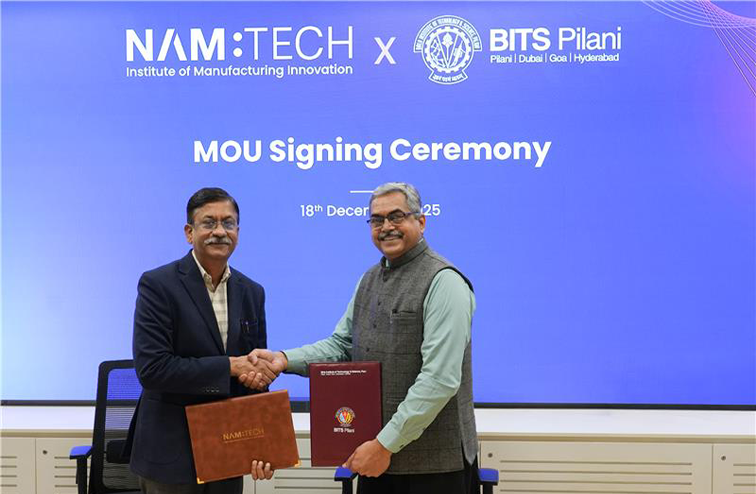

As mentioned earlier, the educational system in India emphasizes conceptual knowledge over practical skills. Interdisciplinary and hands-on skills are essential for Industry 4.0, shifting the paradigm from degree-oriented education to practical skill learning courses. Institutes like NAMTECH provide targeted courses to reskill and upskill India’s youth in the MET sector, emphasising practical knowledge from industry specialists.

The Proposed Plan for Sustainable Development

India’s growth needs to be wholesome, inclusive, and sustainable for it to benefit its citizens in the way the government envisions. Therefore, a holistic development strategy should necessarily incorporate:

- Inclusive growth: Targeted strategies to ensure equitable growth across India’s urban, rural, and semi-urban landscape. It would help to improve the quality of life, physical connectivity, and infrastructure of the nation.

- Social sector development: There needs to be mandatory investments in education, social security, and healthcare. The creation of new jobs in manufacturing is expected to lead to a surge in domestic migration, and Indian cities need to be prepared for this influx.

- Policy reforms: Manufacturing in India can now attract 100% FDI – there needs to be similarly effective reforms in policies surrounding Industry 4.0 as well. India needs a framework for its data and digital economy to propel the new-age manufacturing while factoring in safety and security.

Conclusion

India’s GDP continues to grow, and so does its adoption of modern technologies like AI and ML. Employers are rapidly embracing the application of these technologies to enhance the nation’s manufacturing capacity.

Even though the path is dotted with challenges, there are simple solutions at the grassroots level that can help streamline India’s growth trajectory. In the midst of India’s ambition, the skilled workforce of the nation has the most crucial role to play. Practical-thinking, analytical-minded engineers can fuel the country’s developmental aspirations with their skill and talent.

With NAMTECH, India’s youth can acquire the necessary skills and knowledge required to contribute to the country’s rapidly growing and evolving manufacturing sector.

With experiential programs in smart manufacturing, semiconductor manufacturing, advanced robotics technology, automation, and many more, NAMTECH is on a mission to boost India’s growth with a reskilled and relevant talent force.

Sign up to be a part of India’s growth story by enrolling with NAMTECH – contact us today.

13 June, 2025