Imagine a future factory in Industry 4.0. It’s an orchestration of movement, with machines humming and parts gliding through the air. But behind the scenes, there is a silent and powerful force at work, a powerful duo: pneumatics and automation. In this blog post, we delve into the seamless partnership of these new-era technologies, illustrating how they harmoniously perform the symphony of smart manufacturing.

The Pillars of Smart Manufacturing: Pneumatics and Automation

Pneumatics: The Magic of Compressed Air for Getting Works Done

Pneumatics harnesses air pressure powers and mobilises diverse applications. Essentially, pneumatics put compressed air to practical use for operating various tools and machinery. The technology is prominently used in the manufacturing, engineering, and construction industries.

Pneumatics is a tireless worker who is reliable and robust. It applies compressed air to generate rotary or linear motion to boost actuators, drive pistons, and optimise diverse manufacturing processes. Think of those assembly-line robots with their precise movements—often, pneumatics is the unseen force behind them.

Automation: The Orchestrator of Efficiency

Automation is the brain of the operation, and courses teaching automation are in high demand in India and offer exceptional growth opportunities. Automation uses programmable controllers, sensors, and related technologies to automate tasks, optimise production processes, and boost accuracy.

Explore and apply for future demand courses in India at new-age institutes like NAMTECH to leverage unprecedented demand in smart manufacturing Industry 4.0.

We explored the meaning and functions of pneumatics and automation. Let’s examine their harmonious relationship with your aspiring smart manufacturing professionals.

The Magic of Collaboration: When Pneumatics and Automation Meet

Pneumatics and automation are impressive individually. Together, the magic multiplies and engineering graduates with advanced manufacturing education can leverage the combo to outshine their competition in the market. Here are vital pointers to explain how synergy works wonders for industrial processes, making them efficient and productive.

Speed and Precision: Pneumatics offers exceptional speed and force generation, perfectly complementing automation’s precise control. This translates to lightning-fast and highly accurate operations on the factory floor.

Versatility and Simplicity: Pneumatics boasts a wide range of actuators and control valves, making it adaptable to diverse manufacturing needs. When coupled with pneumatics, automation systems can handle complex tasks while maintaining a user-friendly interface.

Reliability and Cost-effectiveness: Both pneumatics and automation are known for their reliability and require minimal maintenance. This translates to significant cost savings in the long run.

The automation industry has experienced significant advances in digital transformation with pneumatic technologies. New-age technologies to be integrated into smart factories include control valves incorporating wireless tech, sensors, and industrial network interfaces.

Complex digital control features offer access to more innovative, actionable information that significantly improves the efficiency of automation applications. Plug-in valves and manifolds were also created, which meant that all the solenoid valve connections previously linked separately to the PLC could be achieved using a single cable.

Pneumatic valve systems integrate IIoT technology and make it much more advanced, ensuring applications with a whole new level of precision control and pneumatic-driven actuators. Automation enables automatic monitoring and adjusting control functions. Proportional Integral Derivative (PID) controllers with high-tech pneumatic capabilities provide enhanced precision in end-point motion accuracy.

Motion sequences with a collaborative system of pneumatics and automation ensure accurate, fine-tuned, repeatable, and product throughput, increasing the reliability of the production process.

The smart manufacturing program at NAMTECH integrates vital aspects of pneumatics and automation into the curriculum and prepares students for the future of smart manufacturing. Automation systems in future factories will continue to evolve into more advanced, sophisticated, and connected harmony with pneumatic applications.

The combination of automation and pneumatics enhances control capabilities in a manufacturing setup. In the following sections, we will explore key details of iPMP, one of the most sought-after future-demand courses in India, for your quick reference.

iPMP Program in Smart Manufacturing: The Next Level of Pneumatic and Automation Integration

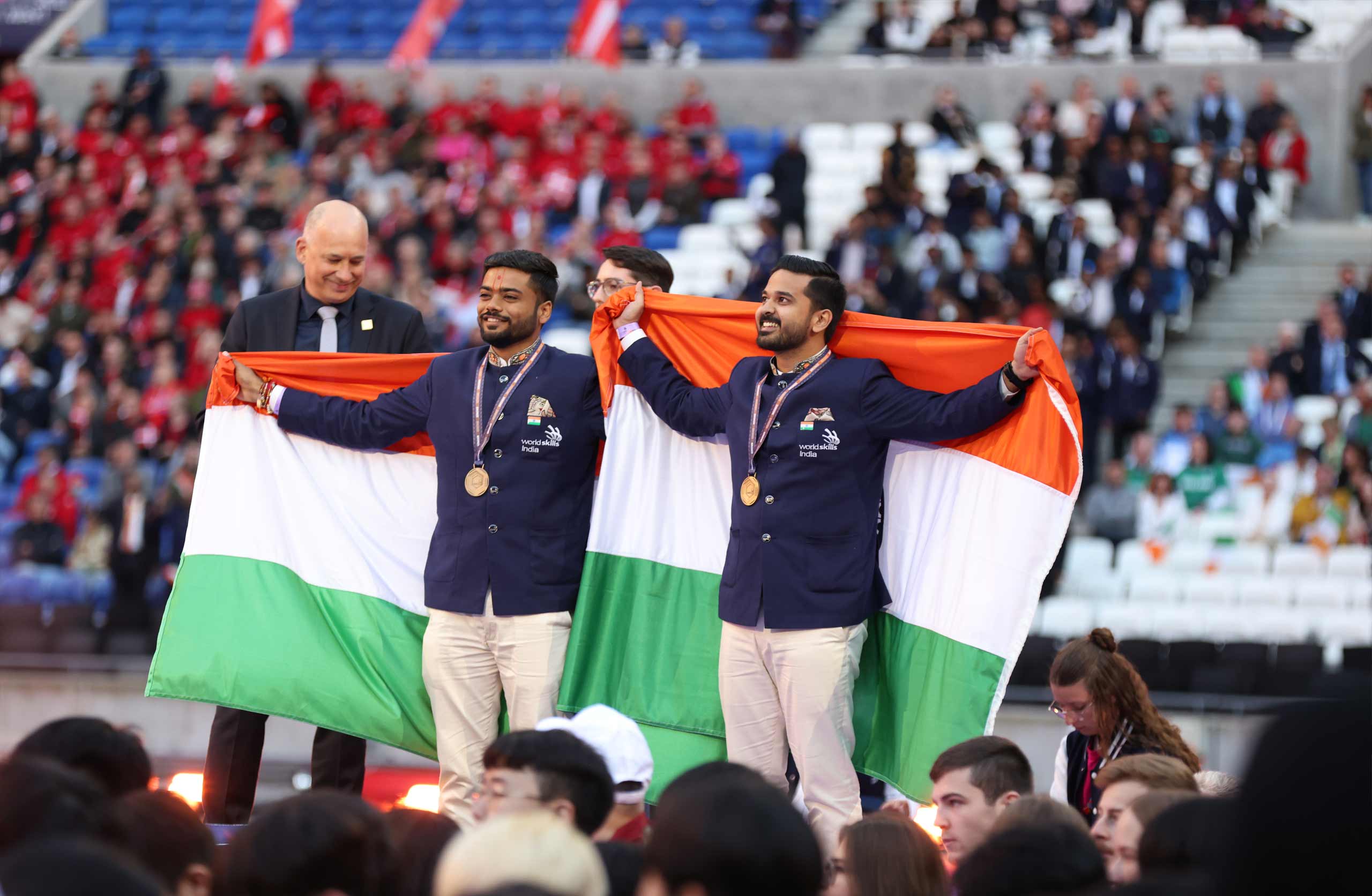

NAMTECH (New Age Makers’ Institute of Technology) offers a customised iPMP in Smart Manufacturing to groom techno-managers for the future of smart manufacturing. Industry-specific master’s program iPMP is an immersive international twinning program ideal for graduates with a BTech/BE degree. It blends real-world Industry 4.0 experiences with a comprehensive curriculum. It fosters a unique learning environment, combining projects, competencies, and theory to shape smart manufacturing professionals.

The iPMP in Smart Manufacturing is a specially curated program for grooming professionals to run future factories using Industry 4.0 technologies. It aims to fulfil India’s ambition to become a developed economy by 2047 by bridging the skill gap between engineers with conventional engineering and engineers required for smart manufacturing.

- Duration: 12 months (residential program) 4 trimesters, each of 12 weeks

- Eligibility: BTech/BE (2019 or later) with a minimum of 65% marks in 10th, 12th, and Graduation

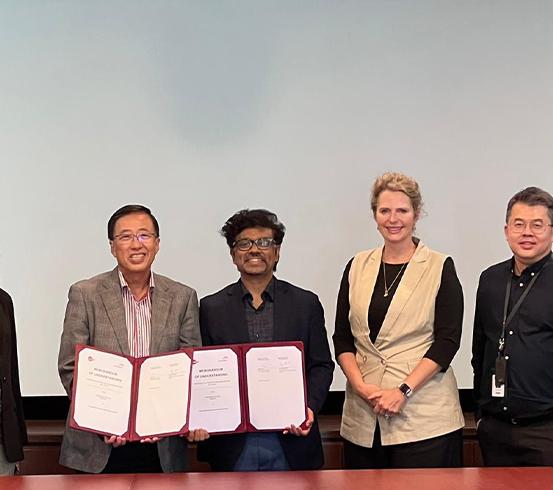

- Campus: NAMTECH India (Campus: IIT Gandhinagar) and TUM Asia, Singapore

Key Highlights of the iPMP Program in Smart Manufacturing

- 1-month Global Immersion Program at TUM Asia, Singapore and TUM Germany

- International faculty from industry and academia

- Up to 100% scholarship

- The industry-aligned curriculum is prepared with industry experts and focuses on building practical skills with experiential activities.

- The curriculum incorporates global values, including digital skills, sustainability, solidarity, industry-ready and well-being.

- Students learn smart manufacturing Industry 4.0 technologies, product design & development, problem-solving & management, and a capstone project.

- Exceptional industry and academic collaborations, including Festo, AM/NS India, Micron, Schneider Electric, Cal Poly, Cisco, Purdue University and more

Conclusion: A Powerful Harmony for the Future

The future of smart manufacturing Industry 4.0 belongs to those who can harness the power of collaboration. Pneumatics and automation are a powerful duo that propels Smart Manufacturing forward. By leveraging advanced manufacturing education, you can design and ensure speed, precision, and efficiency in future factories. Smart manufacturers can create a symphony of productivity by optimising processes, reducing costs, and ensuring a sustainable future for the industry.